Bucket teeth are the key components of an excavator and affect its efficiency. Bucket teeth are in direct contact with ore, sand, rock, and other materials under the action of external forces, and they not only bear strong impacts, but also the bending moment. With different working conditions, the tooth wear varies greatly, and wear life varies. The factors that affect the life of the bucket teeth include the structure of the rock, the blasting situation, the structure and shape of the bucket teeth, and the driver’s operating habits. Besides, chemical material of bucket tooth.

The structure of rock refers to the characteristics of the rock’s material crystallinity, the size of mineral particles, the shape of the mineral and the relationship between them.

According to the normal hardness (how easy or difficult the rock can be destroyed)

Very solid rock f = 15 ~ 20 (solid granite, limestone, quartzite, etc.)

Hard rock f = 8 ~ 10 (such as weak granite, strong sandstone, etc.)

Medium solid rock f = 4 ~ 6 (such as ordinary sandstone, iron ore, etc.)

Unstable rocks f = 0.8 ~ 3

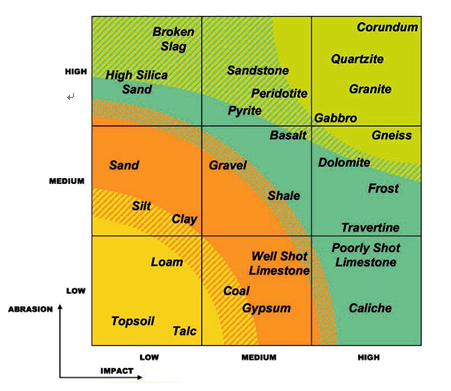

Based on the above normal hardness, I ranked the following rock strengths.

Blasting situation

Good quality blasting conditions can separate hard rocks through the shock wave and airflow of the explosion. The tooth use will decrease, and the life will increase accordingly.

The influence of the structure and shape of the tooth on the tooth life

Different bucket tooth shapes are suitable for different working conditions. If the bucket teeth used do not match the working environment, wear life of bucket tooth will also be greatly affected and sometimes will cause more fuel.

The following are applicable conditions of various bucket teeth.

General Duty – Used in general loading and excavation work. Has longer wear life and greater strength

Penetration – used in densely-compacted material such as clay. Gives enhanced penetration and self-sharpening.

Heavy Penetration – shot rock and tight bank loading where both impact and abrasive conditions are moderate to high.

Heavy abrasion – working in sand, gravel and shot rock. Maximum wear material.

Sharp – maximum gouging and penetration capability less wear materials are self-sharpening.

Twin Sharp – more wear material than sharp tip.

Rock Chisel – used in sedimentary rock, shot rock, high impact rock.

The chemical composition of the tooth also affects the life of the tooth. If yield strength of bucket tooth material is low, bucket tooth will have a certain deformation, if hardness of bucket tooth is low, cutting grooves will be formed. If hardness of bucket teeth is high, the brittleness of the bucket teeth will be increased, which will cause fatigue spalling.

The operating habits of the driver will also greatly affect wear life of the bucket teeth.

For example, the driver who drives the Wheel Loader needs to raise the bucket to prevent the teeth from coming into contact with the ground, and the life of the teeth will also increase.

Post time: Jan-06-2020