OEM China Double Bevel Flat - Bucket wear parts wear protection Heel shrouds bucket corner protection weld-on shroud construction shroud protective earthmoving wear parts – Minter Machinery

OEM China Double Bevel Flat - Bucket wear parts wear protection Heel shrouds bucket corner protection weld-on shroud construction shroud protective earthmoving wear parts – Minter Machinery Detail:

| Heel shroud measurement as below | |||||||

| PART NO | A | B | C | D | E | F | KG |

| HS188 | 150 | 250 | 188 | 178 | 194 | 48 | 23 |

| HS300 | 132 | 252 | 300 | 250 | 210 | 30 | 23 |

| ES6697-2 | 150 | 250 | 188 | 158 | 200 | 50 | 22 |

| ES6697-3 | 100 | 200 | 188 | 178 | 150 | 38 | 13 |

| ES6697-5 | 200 | 300 | 250 | 220 | 235 | 50 | 38 |

| ES6697-6 | 150 | 300 | 188 | 166 | 200 | 50 | 29 |

| ES6697-7 | 250 | 355 | 250 | 220 | 235 | 108 | 80 |

Heel shroud

Welded on heel shroud provides excellent wear protection of the lower outside corner of all types of buckets.

Overlaps joint between floor and sidewall to protect critical high wear area of the bucket.Curved to bottom of the bucket for a proper fit.Bulbous corner for increased material in high wear area.High alloy steel for resistance and weldability.

|

Part Description |

Mechanical Property |

|

Teeth |

Hardness HRC48-52, Impact strength(room temperature)≥18J |

|

Adapter |

Hardness HRC36-44, Impact strength(room temperature)≥20J |

|

Grader Blades C80 |

Hardness HB280-320,Impact Strength≥7J(room temperature) |

|

Cutting Edge 30MnB |

Hardness HB440-480,Impact Strength≥25J(room temperature) |

|

Cutting Edge 16Mn |

Hardness HB330-370,Impact Strength≥40J(room temperature) |

Advantage

1. Fast Delivery Time, lead time is around 35-40days.if stock availability, within one week.

2. Large Inventory, more than 5,000 items.

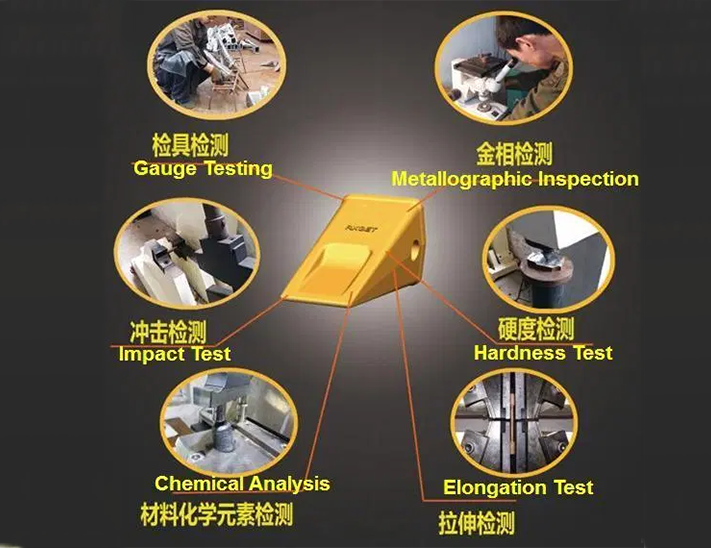

3. Strict Quality Management, testing hardness, impact strength, and test matchable one by one.

4. High impact strength and more wear material

5. Much more reasonable price

6. Professional, our factory has more than 20-year history on g.e.t field.

Quality Management

Impact Testing

Spectrograph

Tensile

hardness

Stock Picture

Shipment Picture

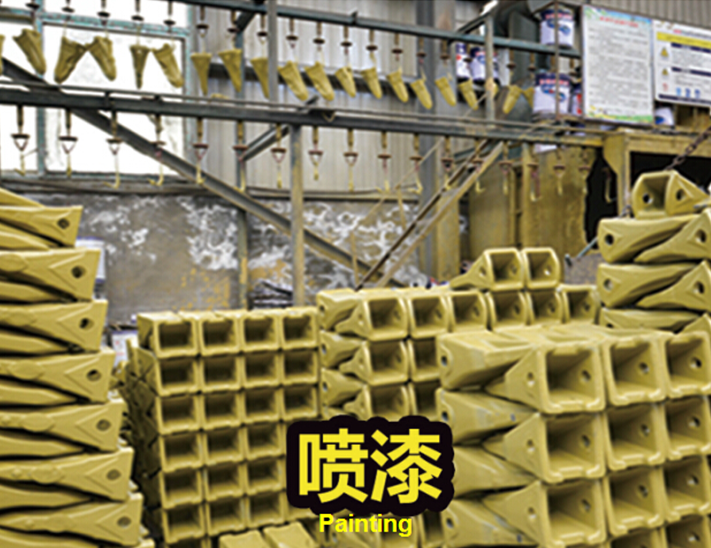

Production Process

1-Mould Design

2-Mould Processing

3-Wax Model Making

4-Tree Assembly

5-Shell Building

6-Pouring

7-Sprue Removal

8-Heat Treatment

9-Product Testing

10-Painting

11-Package

About MINTER Profile

Ningbo Minter Machinery Co.,Ltd is a professional G.E.T located in China.Main products are Bucket teeth,adapter,cutting edge,bolt&nut,pin&retainer Chocky Bars and bucket wear protection. We provide direct replacement parts can be used for excavator,loader,bulldozers,scarifier,grader and snow plows,both construction sector and minning sector.

suit for most machinery brand like Caterpillar,Komatsu, Hitachi, Hyundai,Doosan,Volvo,JCB and some for Chinese machinery such as Sany XCMG,Liugong and so on.

There are complete & professional facilities in each production process.And we pay more attention to high standard for details from raw material selection to goods package and shipping. We are strict with delivery time.And our aime is simple,Committing to provide consistent high quality spare parts with excellent service for customers,to meet customers’ requirements and make effort to enlarge their market share and establish long-term cooperation with customers.

With strong technology term back-up and rich knowledge&experience on this field,we are able to provide R&D development to meet costomization requirement.

We focus on this industry. Join us to explore market together and pursuing what we want!

Q & A

Firstly, we will check our stock if availability, if no stocks, lead time is around 35-40days.

Promise no breakage happens.

Once breakage happens, we will have our technique team check and analyze. we will replace one by one for free if we should be responsible.

We are specialized in providing G.E.T parts like bucket teeth, adapter, cutting edge, side cutter, Protector, shank, ripper teeth, shank guard, fastners like bolt, nut,pin and retainers. Mainly for heavy machinery like excavators, loaders, dozers, motor graders and scrarifiers.

Yes, we are a manufacturer located in Ningbo China. And we welcome to visit our factory.

No Moq. But if order quantity is less than 3tons, we have to surcharged for inland freight charge, port operation charge, file charge, export declaration charge etc..

We can provide PC1250, Caterpillar J800 spare parts,81 series as well. We are also striving into minning industry, expecting bigger parts can be casted later soon.

Product detail pictures:

Related Product Guide:

Cooperation

OEM China Double Bevel Flat - Bucket wear parts wear protection Heel shrouds bucket corner protection weld-on shroud construction shroud protective earthmoving wear parts – Minter Machinery , The product will supply to all over the world, such as: Mexico , Finland , panama , We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality products and good after-sales services. Up to now, our products have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.